Electroplating anodes are utilized to make items in numerous plating industries, including the pressure driven industry. The most well-known utilizes for electroplated items are chrome covered oil siphon drill flights, water powered chambers, transport flights, sheets and tanks where it would be illogical or excessively costly to make the thing completely out of the plating metal.

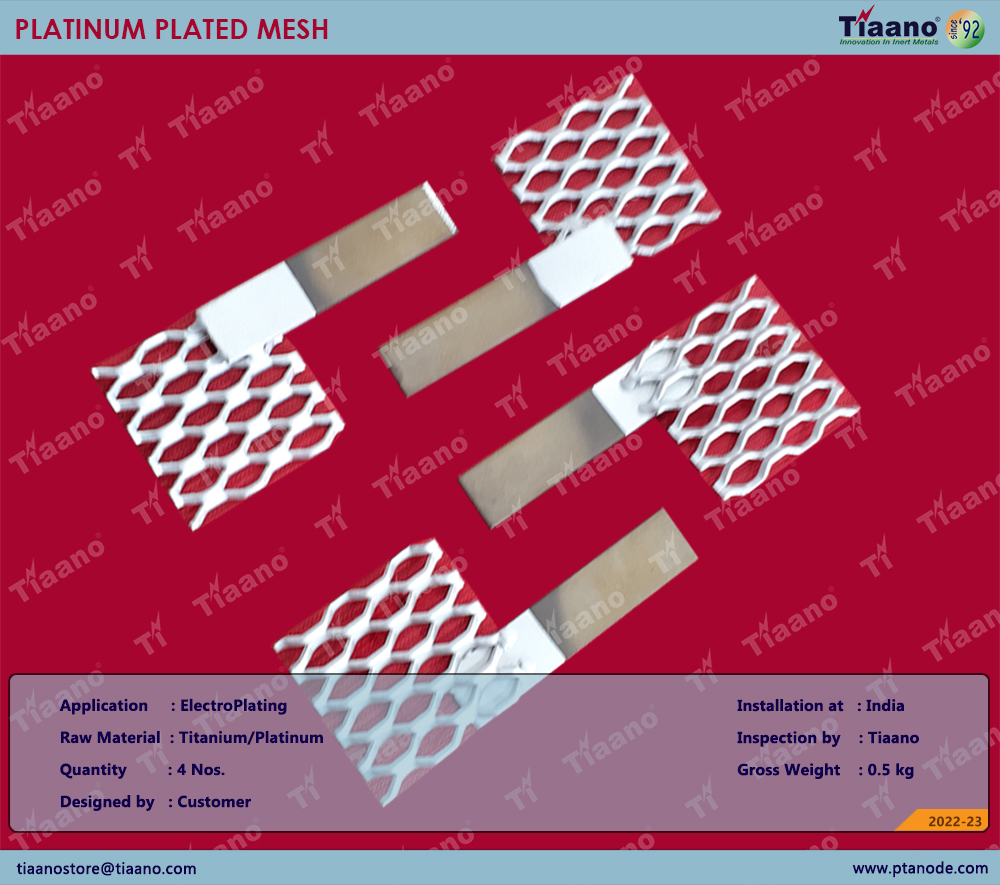

Platinum is one of the six metals in the "Platinum" gathering of valuable metals, which are all brilliant impetus materials. Platinum is conductive, artificially steady and exceptionally impervious to oxidation and erosion. It has a brilliant dim variety and can be cleaned to an assortment of completions.

Platinized titanium anodes ought to be supplanted when they begin giving indications of chipping or chipping away of the platinum covering or a staining shows up. Care ought to likewise be taken to supplant dissolvable anodes when they become excessively little.

Significant Applications:-

Hard chrome plating (cylinder rings, printing chambers, and so on.)

Valuable and non-valuable metal electroplating

Electronics and semiconductor industry

Electrolytic recuperation of metals

Substance process designing

Rapid Gold, Silver, Platinum and Palladium applications