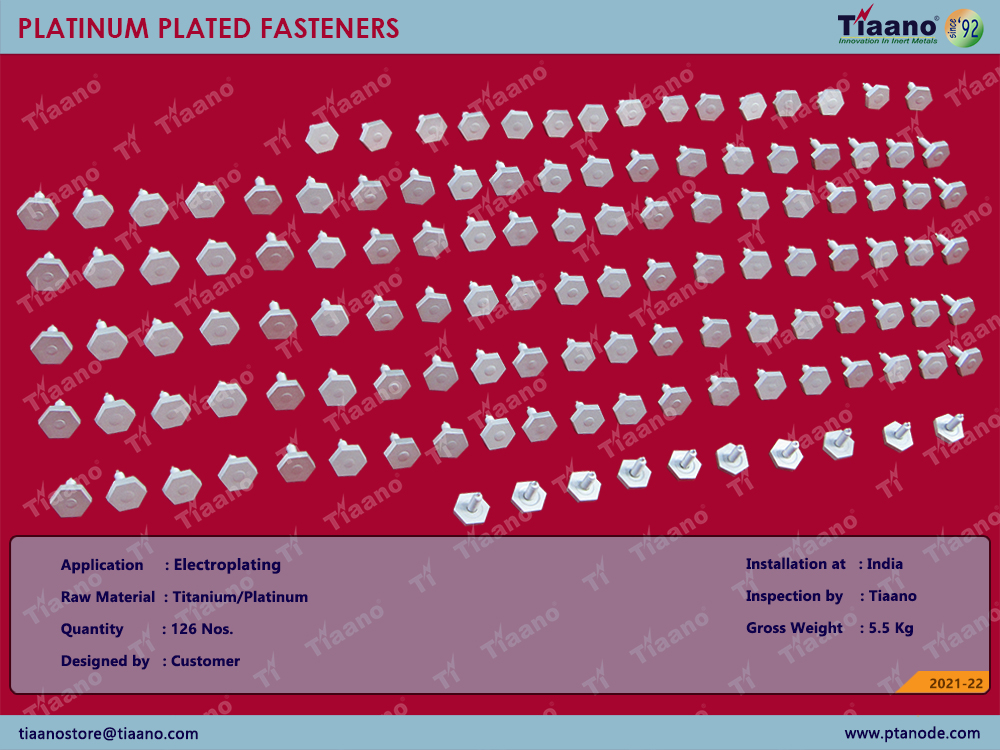

Tiaano Established in 1992 at Chennai in Tamil Nadu, is leading Exporter, Manufacturer, and Supplier of Titanium Anodes. Tiaano has made a reputed name for themselves in the market with high quality Titanium Anodes, Electrodes, Fasteners, Vessel and Equipments with Platinum Plating and MMO Coating.

Platinum Plated Titanium fasteners are used in applications where high strength to weight ratio, excellent resistance to stress corrosion cracking, high corrosion resistance, and good fatigue strength are desired. These application include:

Military and commercial maritime applications

Submarine masts and exteriors

Landing gear and engine components

NASA launch vehicles and spacecraft

Commercial and military satellites

Are You Looking for Titanium Fasteners?

No matter what you are trying to do we have the materials you need. Whether it’s titanium fasteners, various castings, or even forgings we have what you need. How are we so good at getting you what you need? Well, we have been doing this for 30 years. Plus, we have an ISO 9001 certification, which allows us to provide a full range of value-added services to our customers.

When it comes to fasteners, titanium has a higher tensile strength and resistant to high temperatures, seawater, and galvanic corrosion. While titanium might not be ideal for every application due to its moderate ductility and low work hardening rate, it is ideal in many aeronautical and naval applications.