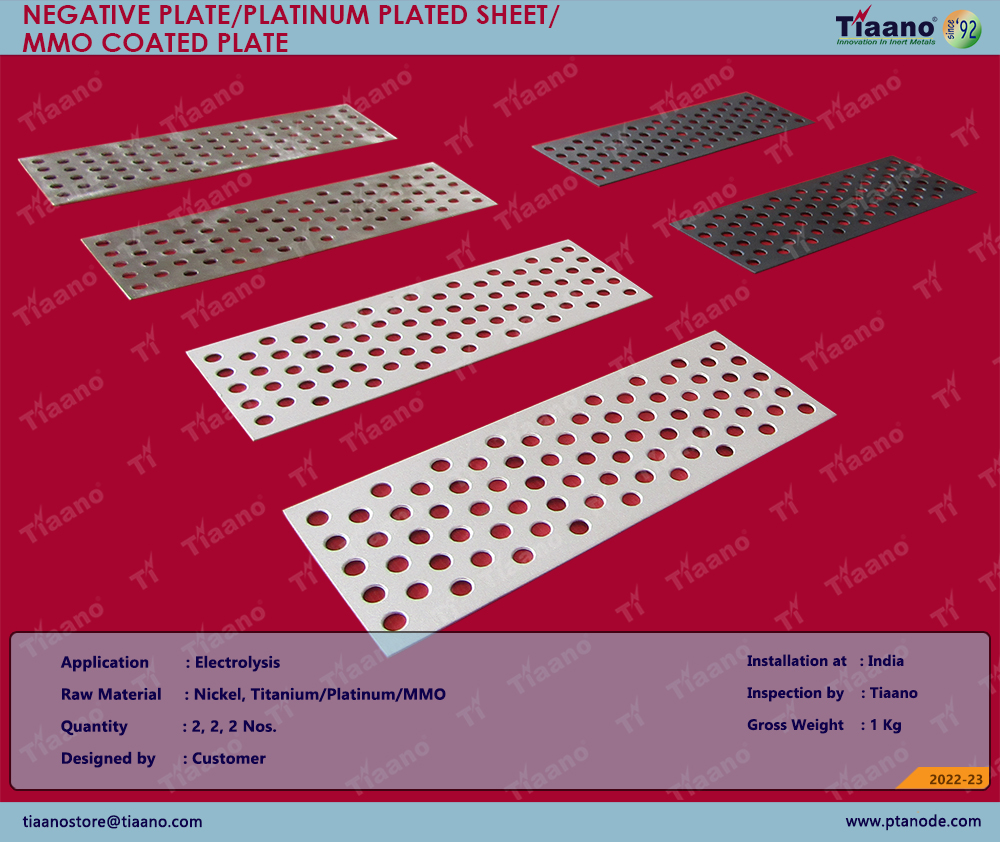

Tiaano offers wide range and types of Platinized Titanium Anodes for various Electro Chemical and Electrolysis Application. Platinum titanium anode is an insoluble anode, platinum plating and titanium substrate with a solid and stable performance.

Technical characteristics of Titanium Anode : High current efficiency; excellent corrosion resistance; long electrode life; electrode shape can be designed according to user needs; electrode substrate can be reused several times; no pollution to the medium (electrolysis); can withstand higher Current density.

Electrolysis Process : Electroplating, Electro Winning or electroextraction, Electrosynthesis, Electrodialysis, Drinking Water electrolysis, Cathodic Protection, Sodium Hypochlorite, HHO Generator, Swimming pool disinfectant, Perchlorate protection, Chlor-alkali industry etc...

Why are Platinum electrodes used in electrolysis?

1. Electrolysis is the process of passing the electric current in a solution that will chemically affect the solution.

2. This chemical change will further lead to the loss or gain the electrons in the solution.

3. Platinum is the metal that belongs to the periodic table, and it belongs to the noble metal group.

4. Noble metals mainly include Gold, Silver, Iridium, and Platinum.

5. Platinum is used in an electrochemical cell as it is resistant to oxidation.

6. It is less reactive so it does not easily react with any chemical substance.

7. It will also not take part in the redox reactions, that occur in an electrochemical cell.