The new insoluble titanium anode has the advantages of high Electrochemical catalytic performance, significant energy saving, high stability, no pollution to the plating solution, light weight, and easy replacement. It is widely used in various electroplating anodes or auxiliary anodes, and can replace lead anodes. , Long service life, is widely used in electroplating non-ferrous metal industries such as nickel plating, gold plating, chrome plating, zinc plating, copper plating, etc.

Titanium is non-dissolvable and stable in water. It will keep going for a long time [20, 30 or more] without eroding. Its sturdiness, strength, and non-poisonousness pursue it the decision of material to specialists and clinical researchers use for their embedded clinical gadgets like fake joints and pacemakers. Likewise, in light of the fact that it's so sturdy and non-attractive it settles on it the best decision of metal to build a water ionizer terminal.

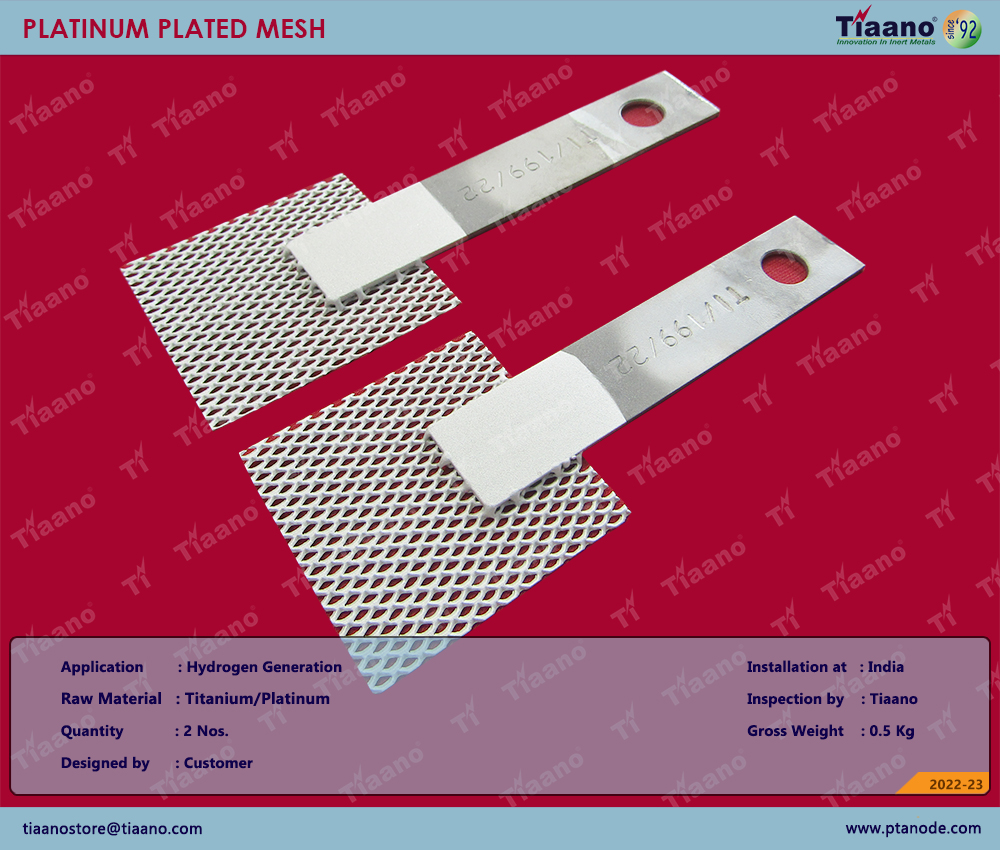

Project Details for Platinum Coated Titanium Mesh:-

Tiaano: Manufacturer and Supplier of Platinum Plated Titanium Mesh Metal Anode.

Anode: Platinized Plated Mesh Anode, Platinized Plated Metal Mesh Anode, Platinized Expanded Mesh Anode, Titanium Mesh Electrode with Platinum, Platinum Anode

Application: Electrolysis Anode, Electro Plating Anode, Gold Plating Anode, Rhodium Plating Anode

Installation at: India

Reference Link:

http://www.ptanode.com/MetalFinishingAnode.aspx

http://www.ptanode.com/post/Platinized-Titanium-Cylindrical-Mesh-Anode.aspx

http://www.ptanode.com/post/Platinized-Titanium-Mesh-Anode-1.aspx

http://www.ptanode.com/post/Gold-Plating-Anode.aspx