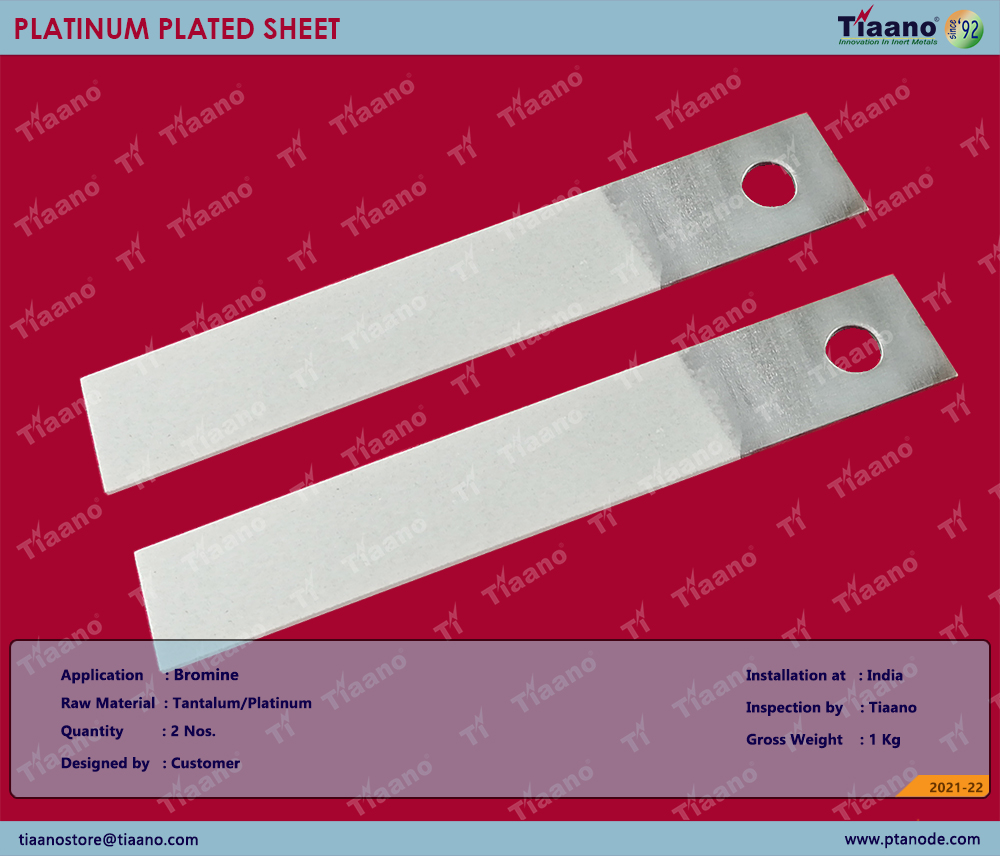

Titanium and titanium alloys find extensive use in electrolytic cells. For example, in electrolytic cells useful in the Production of Bromine, evolution of chlorine, alkali metal hydroxide, and hydrogen, the anodes are frequently platinum coated titanium anodes.

Similarly, in electrolytic cells for the production of Bromine, the anodes are frequently platinum plated titanium anodes while the cathodes are uncoated titanium.

One problem encountered in the use of titanium electrodes, especially as cathodes, is the uptake of hydrogen by the titanium and the consequent formation of titanium hydride within the electrodes. Another problem is the high overvoltage of hydrogen evolution on titanium cathodes.

It has now been found that the rate of titanium hydride formation may be reduced and the hydrogen overvoltage may be reduced if the titanium is present as an alloy with a rare earth metal.

Major Advantages of Platinized Titanium based Electrolytic Cell:-

In the production of Bromine, after using titanium anode, the product quality is high, the bromine concentration is high, and energy consumption is saved.

It is highly resistant to corrosion and can work in many corrosive and special electrolytic media.

Avoid the short circuit problem, thus improving the current efficiency.

Titanium anodes are light in weight and reduce labour intensity.

With metal anodes, high temperature, high current density operation of the chlorate bath is possible.

The low overpotential characteristics, the bubbles between the electrodes and the electrodes are easily eliminated, which is an important reason for the voltage drop of the metal anode electrolytic cell.